Installation of Technical Stage Hardware & Software

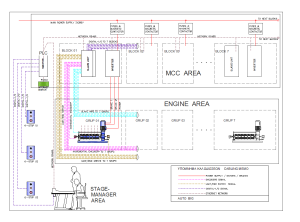

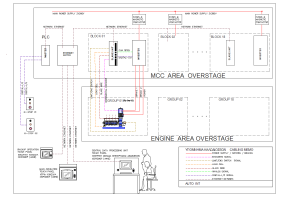

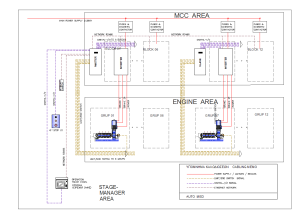

The central Master Device control panel consists of a PLC that is linked through a communication network with SLAVE mechanisms, which are set up on the panel. Through PLC, each SLAVE mechanic is guides their respective INVERTER rotational speed controller, according to the user’s options. For example, Ethernet and Can Open are among the fastest and safest state-of-the-art networks controlling automation systems in real time. Communication between INVERTER – SLAVE PLC, as well as between SLAVE PLC and PLC – Master device, is fast and easy, requiring very few cablings and, as a result, having the advantage of avoiding technical problems.

The central Master Device control panel consists of a PLC that is linked through a communication network with SLAVE mechanisms, which are set up on the panel. Through PLC, each SLAVE mechanic is guides their respective INVERTER rotational speed controller, according to the user’s options. For example, Ethernet and Can Open are among the fastest and safest state-of-the-art networks controlling automation systems in real time. Communication between INVERTER – SLAVE PLC, as well as between SLAVE PLC and PLC – Master device, is fast and easy, requiring very few cablings and, as a result, having the advantage of avoiding technical problems.

The use of the INVERTER rotational speed controllers offers the potential to increase or reduce accordingly the maximum and minimum speed. The operator can change these values within accepted limits as postulated by official specifications. Through INVERTER, the mechanism allows us for ramp acceleration – deceleration, in order to avoid any shocks during the onset or termination of motion. Through the real position mode (Encoder HTL + Can Open +Master device), it is possible to be aware at all times of the exact position of mechanism without the need of resetting.

Another advantage is the concerted movement of mechanisms during a show or even during maintenance period. For safety reasons, high-tech Slake wires are used to control wire ropes. All settings are made from the touch screen control panel. Through the touch screen, we can receive information about potential overloading and problems of the system.

The Internet switch gives the potential for distance/remote monitoring and correcting any occurring problems via INTERNET.

Last but not least, it is possible to expand the system without the need of making high-scale interventions to the existing installation.  Extensibility (Q functions).Potential for programmed movements by the groups directing every Act, (If the system is expanded with the appropriate Directing Programs). The potential for direction mode memories helps the Director to have “ready” each direction mode stored in the stage tower and actuate it whenever needed. In this way, he can prepare more than one act for one or more shows.

Extensibility (Q functions).Potential for programmed movements by the groups directing every Act, (If the system is expanded with the appropriate Directing Programs). The potential for direction mode memories helps the Director to have “ready” each direction mode stored in the stage tower and actuate it whenever needed. In this way, he can prepare more than one act for one or more shows.