General

The safety level of a machine is determined by its designer according to their judgment, viewpoint, experience and consciousness. There is always some Standard Regulation the designer has to comply with. No machine is absolutely safe apart from the fixed part.

The Greek Regulation does not cover Stage Engineering machinery. Until the European Standard gets fully updated, designers of this type of machinery can very well be based on DIN (Deutsches Institut für Normung) and BS (British Standards).

Below we will refer to a security level as defined by German standards regarding all individual machinery items with an industrial design portfolio that are in a production process and can be officially certified.

Industrial Design Standards

When a machine item is constructed, every effort has been made to ensure your own safety. Nothing is more important than prevention.

Motor-driven hoists belong to the general category of Industrial Machinery: machines operating with power energy, to formulate or move materials by cutting, tapping, pressing, rolling, using electrical/ optical/ thermal techniques or by combining all different methods; also, machines or equipment used together with the machinery mentioned above to transport raw materials, semi-finished products or tools for assembly or dismantling, for spraying or coating applications, for tests and inspections or for packaging.

This machine item has been designed and constructed in compliance with Regulations and Directive 2006/42/ΕC “Safety of Machinery”, (Directive 2006/42/EC has been in force since 29/12/2009 to replace Directive 98/37/ΕΚand pursuant to International Standards: ΕΝ 292 -1,292-2, DIN 56921-11, DIN 56950-3,5,7,ΕΝ 294,ΕΝ 349, ΕΝ 60204-1.

Calculation Standards

This part refers to high-standard multiple constructions with the use of weight lifting machines. Stage Engineering is not a product; it is a whole Technical Project. All individual aspects are interconnected in order to compose and bring out a common project. Hence, the Technical Study determines safe coordination and co-operating of individual accessories and machinery items. Regulatory instructions are oriented along two main axes: a) Safety factors (related to loads, friction, brakes, torques, powered), and b) Systems dealing with all different aspects. With reference to the first axis, in general, provision for safety factors in Stage Engineering is much higher than required by Regulations. As for the second axis, there is provision for double systems to cover individual aspects at the discretion of the design planners. Therefore, sometimes there is need to install a second electromagnetic brake, as well as Hardwire & Software with double safeguards.

In supplementation to National Legislation, the following also applies:

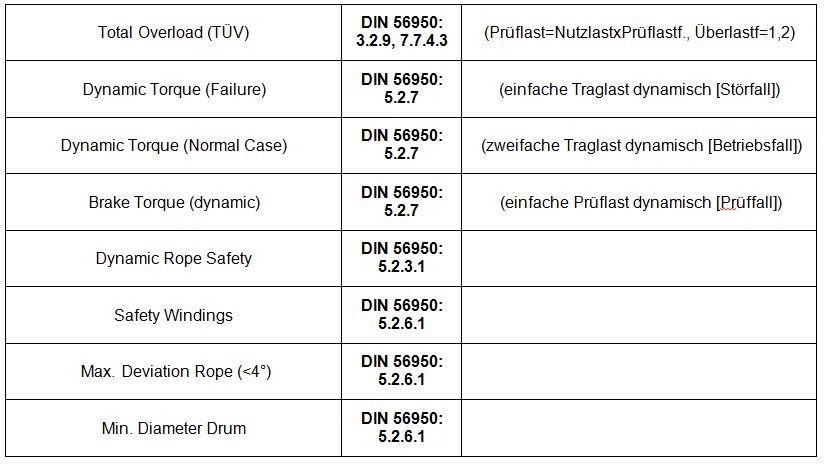

As a rule, parameters demonstrated in the following Table are calculated and conform to standards.

The safety level of software and driving systems may be up to SIL3.

Rules & Standers Table

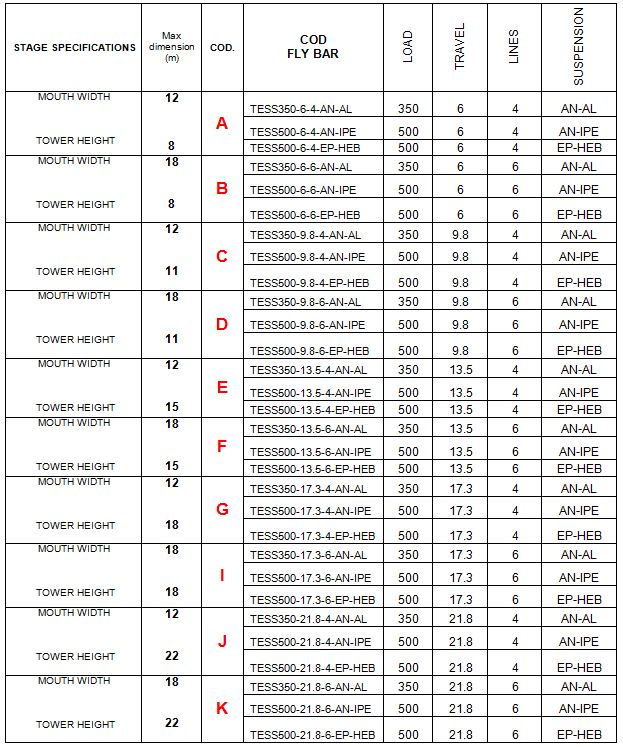

Fly model choice at Stage

COMMENTS

WORK IN This cod (TESS) respects the Fly Bar system

LOAD Load is arranged by stage manager

TRAVEL Travel is the max. vertical distance of movable fly bar

LINES Number of wire ropes

SUSPENSION Type of beam GRID. The pulleys of Fly Bar depend on it (AL, IPE, HEB)

REST The same criteria are also used for all the rest mechanisms